HEIDELBERG, Germany, March 14, 2024 /PRNewswire/ — NEC Laboratories Europe and NEC Laboratories America have developed MateriAI, an AI-based, material design platform that accelerates the development of new, environmentally friendly materials.

The prototype platform was initially designed to overcome major hurdles in the creation of new synthetic, organic and biobased polymers, such as rubber and plastics. Koichi Funaya, Chief Technology Architect at NEC Laboratories Europe, explains: “To develop any new material, scientists must first navigate the often exhaustive amount of existing information about related materials and then short-list potential new molecular structures for the development of new materials. MateriAI transforms this process by making it much faster, semi-automating the aggregation of data, while using AI to suggest new polymers for material design.”

MateriAI uses a purpose-built, polymer-based large language model to gather polymer information, then applies physics-informed machine learning to capture its complexity, including the micro- and macro-level structures of polymers. The platform’s large language model is trained on a vast number of resources to collect and link material knowledge, critical design information and processes – greatly enriching the information used for new material design.

Standard analytical computational approaches, even when using high-performance computing, are inadequate to handle the complexity of biomaterial structures. However, improvements in how MateriAI processes complex information enables the platform to run on CPU- and GPU-based computer systems designed for standard computational workloads.

Says Funaya: “Many organic polymers have long, intertwined polymer chains, which makes calculating their potential interaction with other polymers difficult. A vast amount of supporting information about the manufacturing processes must also be considered. For example, when developing new types of rubber, the relationship between polymer chains, fillers and additives in rubber mixtures – and the cross-linking of rubber materials – all need to be understood.”

Based on its large language model, MateriAI integrates these layers of complexity and uses physics-informed machine learning to provide insights into the creation of new materials. This approach eliminates the need for a complex natural language processing pipeline.

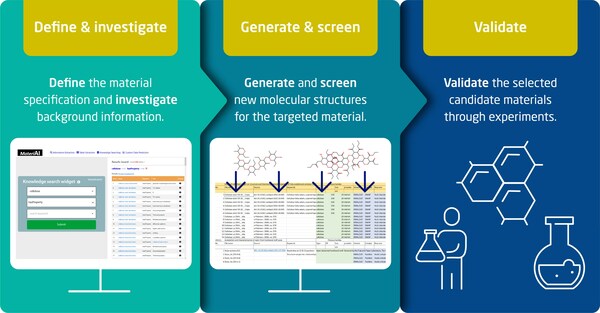

Using the platform’s intuitive user interface, users enter the mechanical, temperature and electrical properties of the polymer they would like to develop, including any conditions for its manufacturing methods. Candidate molecules are displayed visually, and conditions can be updated on the fly. Changes to models are displayed in real time.

Dr. Martin Renqiang Min, Department Head of Machine Learning at NEC Laboratories America says: “MateriAI learns with even the smallest amount of data and applies physics-informed machine learning to accurately predict physical material properties. The platform lets material scientists focus on material-design tasks, removing the burden of background investigation and material property predictions.”

This approach is a radical departure from previous material-design frameworks, letting material scientists design materials for use cases where a large part of the existing material knowledge is unknown.

In the coming months, NEC will expand its customer trial of MateriAI within the polymer market and extend its application to other industries. A commercial launch of the prototype platform is planned within the next 12 months.

Photo – https://mma.prnasia.com/media2/2358076/NEC.jpg?p=medium600