Siemens is enabling faster, more cost-efficient innovation and collaboration across the entire product lifecycle for SMEs through cloud-based SaaS and digital twin technologies.

Technology advancements like AI and automation are driving increased consumer demand for innovative, smart and connected products, and businesses must adapt quickly to stay competitive. In Singapore, small and medium enterprises (SMEs) make up 99% of all enterprises and provide 70% of employment, making them vital drivers of both the economy and the nation’s digitalization journey.

To remain resilient and relevant, SMEs must adopt a digital strategy that transforms the entire product design-through-manufacturing lifecycle. Affordable, scalable and flexible software are essential, and software-as-a-service (SaaS) and digital twin technologies offer a key competitive advantage for SMEs.

(Credit: Getty Images)

Addressing SME’s challenges in Singapore

SMEs often face challenges with structural limitations like capital, workforce, and infrastructure. They also struggle with digital readiness when adopting advanced technologies like AI and automation. So while these technologies promise immense benefits such as increased operational efficiency, and real-time insights, their implementation can be hampered by resource constraints, skill gaps, and insufficient technical infrastructure.

Consumer demand for smart, connected products is pushing manufacturers to speed up time-to-market. As a result, efficient collaboration among employees, stakeholders, contractors, suppliers, and partners is essential to overcome design and supply chain challenges.

Software as a Service (SaaS) for SMEs

Cloud-based product lifecycle management (PLM) software is required to implement a digital transformation strategy and streamline processes from design through manufacturing. PLM software provides great value to SMEs by connecting and aligning data, company and vendor business processes, and technologies to help develop and bring quality products to market faster.

It is now easy for SMEs to adopt cloud-based SaaS PLM solutions without a significant upfront investment. Leveraging the connectivity inherent in SaaS and cloud-based technologies, SMEs can focus on innovative product development and optimisation while providing all employees and their supply chain access to cloud-ready, secure, and connected tools wherever they need them.

Start your digital transformation journey with SaaS

In Singapore, demand for digital tools is fueled by businesses seeking to improve operational efficiencies. IMDA’s Singapore Digital Economy Report 2024 found that 85% of SMEs adopted at least one sector-specific solution in 2023, up from 61% in 2021. Furthermore, those who adopted digital solutions under the Productivity Solutions Grant (PSG) declared cost savings of around 50% on average between 2018 and 2023

Cloud-based SaaS and low- or no-code technologies allow companies to automate processes, unlock productivity gains, and maintain a competitive edge. With today’s advanced SaaS offerings, it is easy to get started using a PLM software solution that has preconfigured engineering and business templates, such as Siemens Xcelerator software portfolio. These include the PLM engineering essentials that SMEs require from MCAD, ECAD and multi-CAD engineering and data management, to bill-of-materials (BOM) and document management, through manufacturing process and data management. Siemens Xcelerator software ensures comprehensive end-to-end connectivity and collaboration with all manufacturing employees, stakeholders, partners, and suppliers. These templates help SMEs mitigate risk, shorten learning curves, and solve critical design through manufacturing challenges quickly and confidently so they can focus on innovation and time-to-profit targets. As a result, innovative SMEs are already leveraging digitalization through SaaS to gain a competitive advantage.

The importance of comprehensive digital twin implementation

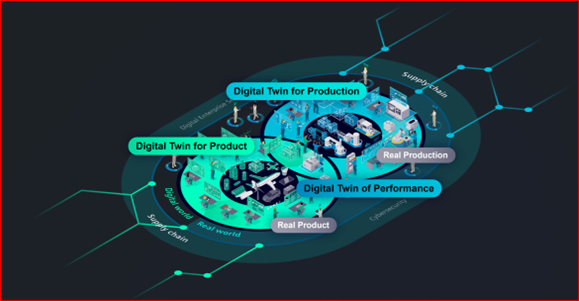

As SMEs advance their digital transformation journeys with PLM software, it is critical to develop a comprehensive digital twin – a physics-based digital representation of a process or a virtual copy of a physical or soon-to-be physical thing. This holistic approach acts as an important decision-making foundation for future business success.

A comprehensive digital twin significantly reduces the need for physical prototypes, thus saving valuable time and resources. Where many solutions offer fragmented capabilities limited to specific functions or processes, the comprehensive digital twin delivers a connected ecosystem spanning design through operation with digital threads. This comprehensive approach offers a precise virtual representation of the product or process flow that matches the exact physical form, functions and behavior of the product.

A* STAR and Siemens’ recent partnership is a prime example. Through joint research projects, they are empowering chemical engineers with digital twin technologies to simulate and optimise processes and design production facilities. This helps companies manage the complexity of product and manufacturing design, and accelerate production timelines. By connecting the real world back into product design, digital twins create a self-improving system that most digital software vendors cannot provide.

According to research from the Digital Twin Consortium, only 8% of digital twin implementations achieve comprehensive integration across the product lifecycle, production, performance analytics, and closed-loop optimization. Siemens is consistently positioned in this highest tier of implementation sophistication through its unified approach to virtualization. Notably, independent research from Frost & Sullivan named Siemens as the innovation leader in their latest Radar Analysis, adding that Siemens’ mechanical computer-aided design (MCAD) solutions continue to deliver cutting-edge innovations, raising the standards for the entire industry.

The seamless integration of products and production, software and automation enables SME manufacturers to design, simulate, test and validate products with the comprehensive digital twin to optimize product and process quality while reducing design cycles. (Credit: Siemens)

Digitalization drives future innovation for sustainable business success

Emerging technologies like AI and automation are pushing businesses to transform the way they work, and fast. But as the digital momentum accelerates, the focus on trust, safety, and responsible tech development remains paramount. Together, Singapore and its global tech partners are not only shaping a vibrant digital ecosystem but also laying the foundation for a secure and sustainable digital future. As a technology leader, Siemens is dedicated to fostering the growth and success of Singapore’s SaaS sector. Through strategic partnerships, investments, and a relentless focus on innovation, Siemens is poised to play a pivotal role in shaping the future of digital transformation across industries.